Contact Us

- Solutions

- Resources

- About

- Contact Us

close

Optional callout banner for highlighted news or events

Learn More

Benefits of Lyophilization

Lyophilization is a drying process commonly employed for thermolabile materials where a solution of the labile active, along with excipients, is converted to a stable solid cake for storage, distribution, and dosing upon aqueous reconstitution. Drug companies have inclined towards lyophilization for the formulation of pharmaceutical products. Benefits include:

Biopharma Quality is Stabilized

The demand for biopharmaceutical products like vaccines, proteins, and cell and gene therapy is increasing, positively impacting the lyophilization market. These drugs require freeze drying for better stability and shelf life. In 2021, biopharmaceutical companies lead the lyophilization market end-user segment, spending more than $323.6 million on lyo services and representing 34.5% of the lyo market in 2022.

For both clinical- and commercial-scale production, biopharmaceutical companies prefer lyophilization techniques for stabilizing the quality of their products. The quality of biopharmaceutical products like antibodies, vaccines, peptides, enzymes, and chemical API remains unchanged once it undergoes freeze drying, which enables an increase in the shelf life of the product. At least 41% of biological drug products requiring freeze drying/lyo processing and because continual growth is expected due to development and availability of more complex drugs.2 As the number of biopharmaceutical and biotechnical companies continues to accelerate at a rapid pace, the traction for lyophilization equipment and services will drive the lyophilization market in the near future.

Freeze Drying

The equipment used to dry solutions or suspensions at or below freezing points of liquids is called a freeze dryer or lyophilizer. Lyophilization is carried out in laboratory-scale, pilot-scale or production-scale freeze dryers, depending on the requirement of the drug developer. Technological advancements in freeze drying equipment or lyophilizers address the needs of customers so that the quality of the products can be maintained without adverse effects on scalability. These advancements are leading to growth of the lyophilization market, with freeze drying estimated to hold the highest market share of 68.7% in the year 2022.

Because temperature is a crucial parameter for pharmaceuticals and biopharmaceuticals, freeze dryers can easily optimize the shelf temperature and chamber pressure so that the quality of the product is not hampered while it is below its critical point. These freeze dryers maximize the sublimation rate as well. Freeze dryers are regularly designed with four basic components: a drying chamber, a vacuum pump, a heat source, and a condenser.

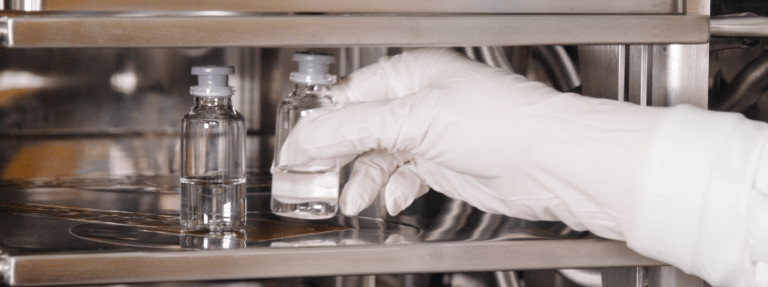

The chamber in which product is placed for freeze drying is the drying chamber. In most cases, the product chamber contains a number of shelves, temperature, and vacuum sensors as well as mechanisms to allow the shelves to move for stoppering purposes. The number of shelves that can be fitted is determined by the size of containers or products to be dried.

Part of this segment includes tray-style dryers. Tray freeze dryers have a single, large reservoir for the dried substance. They usually have rectangular reservoir with shelves on which products, such as pharmaceutical solutions and tissue extracts, can be placed in trays, vials, and other containers. Tray freeze dryers help provide a balance of barrier protection and breathable vapor transmission.

CDMOs Offset Lyo Time and Costs

The growth of the lyophilization market is restricted owing to the cost associated with the various types of equipment. Overall setup costs can vary from $2,000 to more than $10,000. Along with the higher costs, the lyophilization process is time-consuming. The time and high cost of large-scale lyophilization setups restricts investment from small and medium-scale companies. But there are contract development and manufacturing organizations (CDMOs) that offer lyophilization services for pharmaceutical drug development and manufacturing processes, providing the end product to companies after performing the lyophilization process. As the adoption of the lyophilization process is being increasingly accepted in pharmaceutical as well as biopharmaceutical companies, the number of organizations that provide lyophilization services is also increasing.

A CDMO that offers lyophilization services helps the drug sponsor achieve their goals of developing and manufacturing commercial products with the highest quality standards. For instance, the CDMO can facilitate the drug development and manufacturing process by offering aseptic fill finish and lyophilization, bulk lyophilization, and non-aseptic fill-finish and lyophilization.

Like what you read? Share with your network: